Two facts about ASUS NUC mini-PCs that you might not know: first, their return rate as of June 2025 is impressively low at just 1%. Second, they stand out in the market with a mean time between failures (MTBF) of 50,000 hours. For those that are counting, that’s nearly six years of nonstop 24/7 use. If you’re working to maximize your return on investment for the next set of mini PCs for your business or organization, there’s no better choice.

But perhaps you’re wondering just how ASUS NUCs can stand out so much against the competition when it comes to reliability. Take a moment to travel behind the scenes with us. The trusted performance that an ASUS NUC provides begins with a crushing gauntlet of durability tests — and only the designs that pass through these tests make it to your business.

Military-grade durability tests provide a starting point

Lots of companies out there boast about the “military-grade durability” of their products, but it’s worth digging into what that actually means. Established by the United States Department of Defense, MIL-STD-810H guidelines lay out engineering direction and testing methodologies to ensure that all equipment acquired by the military offers a baseline level of reliability.

When a company says that its products pass military-grade durability tests, you should immediately ask which tests and how many. There’s no certification program for these tests and no standardized number of tests which a product must pass to brand itself as military-grade. What’s more, the specific MIL-STD-810H tests used might not be relevant to your business, and they might not force a testing subject to endure the level of hazard that products might encounter in your usage scenario.

At ASUS, we exceed industry standards when it comes to testing products according to MIL-STD-810H specifications, subjecting our products whenever possible to a larger range of tests than our competitors, and providing clarity on which tests our products pass.

Which MIL-STD-810H tests are ASUS NUCs subjected to?

For the ASUS NUC lineup specifically, we focus on MIL-STD-810H tests that demonstrate resistance to the environmental hazards that these mini-PCs might face in enterprise deployments. ASUS NUCs serve in environments ranging from corporate offices to factory floors, from aircraft to agricultural settings, and from humid tropical locations to bitterly cold regions.

Each of these locations presents its own hazards, so we subject ASUS NUC designs to extremes of temperature, altitude, humidity, shocks, and vibration.

- High-temperature test: Products endure temperatures ranging from 33° to 71° C for seven days while non-operational, and then temperatures ranging from 32° to 49° C for three days while operational.

- Low-temperature test: This test subjects ASUS NUCs to temperatures ranging from -25° to -33° C for seven days while non-operational, followed by temperatures ranging from -21° to -32° C for three days while operational.

- Altitude tests: In these two tests, products endure a low-pressure environment, first in a simulation of storage conditions and second with the product in operation.

- Humidity test: Products endure 95% relative humidity and temperatures ranging from 30° to 60° C for ten days while non-operational.

- Shock test: ASUS NUCs are subjected to drops from a height of 100mm while operational.

- Vibration test: Products are vibrated for 40 minutes along each axis while non-operational.

MIL-STD-810H tests serve as a valuable baseline for determining a product’s reliability, but many of our enterprise customers ask us for testing results in even more extreme conditions. For example, while it’s good to have a mini-PC that’s capable of withstanding a 100mm drop, that’s hardly sufficient to demonstrate that a product can withstand being bumped by an employee and knocked off a standard office desk. For that, we need to go above and beyond MIL-STD-810H.

Torture tests that exceed industry standards

To give your business peace of mind that your ASUS NUCs are built to go the distance, we established a robust series of tests that simulate not only the real product lifecycle of typical mini-PCs, but also the rigors of long-term use.

Our tests start by considering the hazards that ASUS NUCs might encounter in the shipping process. We service customers all around the world, so our packaging needs to survive the trials of transportation on cargo ships, processing in port facilities, and travel through regional delivery networks. ASUS NUC packages are subjected to package drop tests, package vibration tests, and 4000 bumps to simulate harsh shipping conditions.

But environmental hazards don’t stop when you pull an ASUS NUC out of the box, so our tests don’t stop there, either. We put ASUS NUCs through a drop test which far exceeds MIL-STD-810H, raising them to a height of 60cm and subjecting them to a drop across all six faces, three edges, and two corners.

End users aren’t always gentle with the USB ports on their devices. Our specially designed port test makes an ASUS NUC endure 1500 insertion-and-removal cycles to ensure connector durability, functionality, and structural integrity.

Reliable operation in humid and hot environments is especially important for many deployment scenarios, so we check for potential performance and cosmetic degradation due to high temperature and humidity exposure. Our humidity test subjects products to 85% relative humidity and 85° C temperatures for approximately 500 hours – nearly twice as long as the comparable MIL-STD-810H test.

Our high temperature test is formulated to assess whether solder joints will be reliable over a product’s lifetime. In this test, ASUS NUC designs show that they can withstand over 600 cycles in our heat bake tests, which place the products in an environment with temperatures ranging from –40° to 100° C.

MTBF numbers that race to the top of the class

For many businesses, the most important number for any product acquisition is mean time between failure (MTBF). Any company worth its salt will publish an estimated MTBF for its enterprise products, but we take things to the next level when we evaluate the MTBF of ASUS NUC mini-PCs.

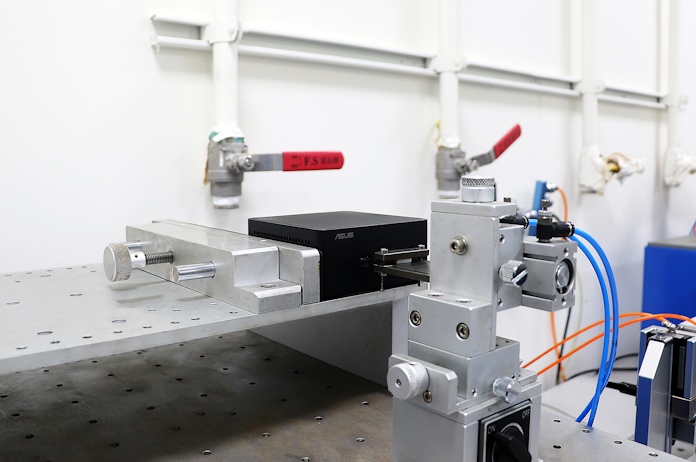

In our MTBF evaluations, we place forty NUC units in a controlled chamber and expose them to a constant 40° C temperature for a full 90 days. The length of the stress test, along with the tough environment that it requires the products to operate in, allows us to guarantee 24/7 reliable operation and assurance of long-term value for our customers.

ASUS NUCs are built tough and ready for business

Put together, these MIL-STD-810H procedures and the additional assessments devised in our own testing facilities serve as an unerring microscope under which no weakness can hide. Subjecting each NUC design to this extensive and rigorous testing process ensures that it can withstand the wear and tear of constant use as well as deployment into harsh environments.

We consistently exceed industry standards when it comes to evaluating the durability and performance of our ASUS NUC product line. If you’re ready to join the many enterprises already taking advantage of the long-lasting performance of ASUS NUC mini-PCs, click here to browse our full lineup.